Your Challenge, Is Our Business

AISUS pioneers remote inspection technologies, delivering industry-leading service solutions globally.

Recent Case Studies

Remote Visual Inspection: Onshore Windfarm Cable Duct

Overview The client required AISUS to inspect the full length of a 94m duct used to pull cables through from an onshore windfarm. Previously failed to be inspected by other operators the client needed AISUS specialised inspection equipment to gather urgent and actionable data – finding the extent of the blockage and getting the […]

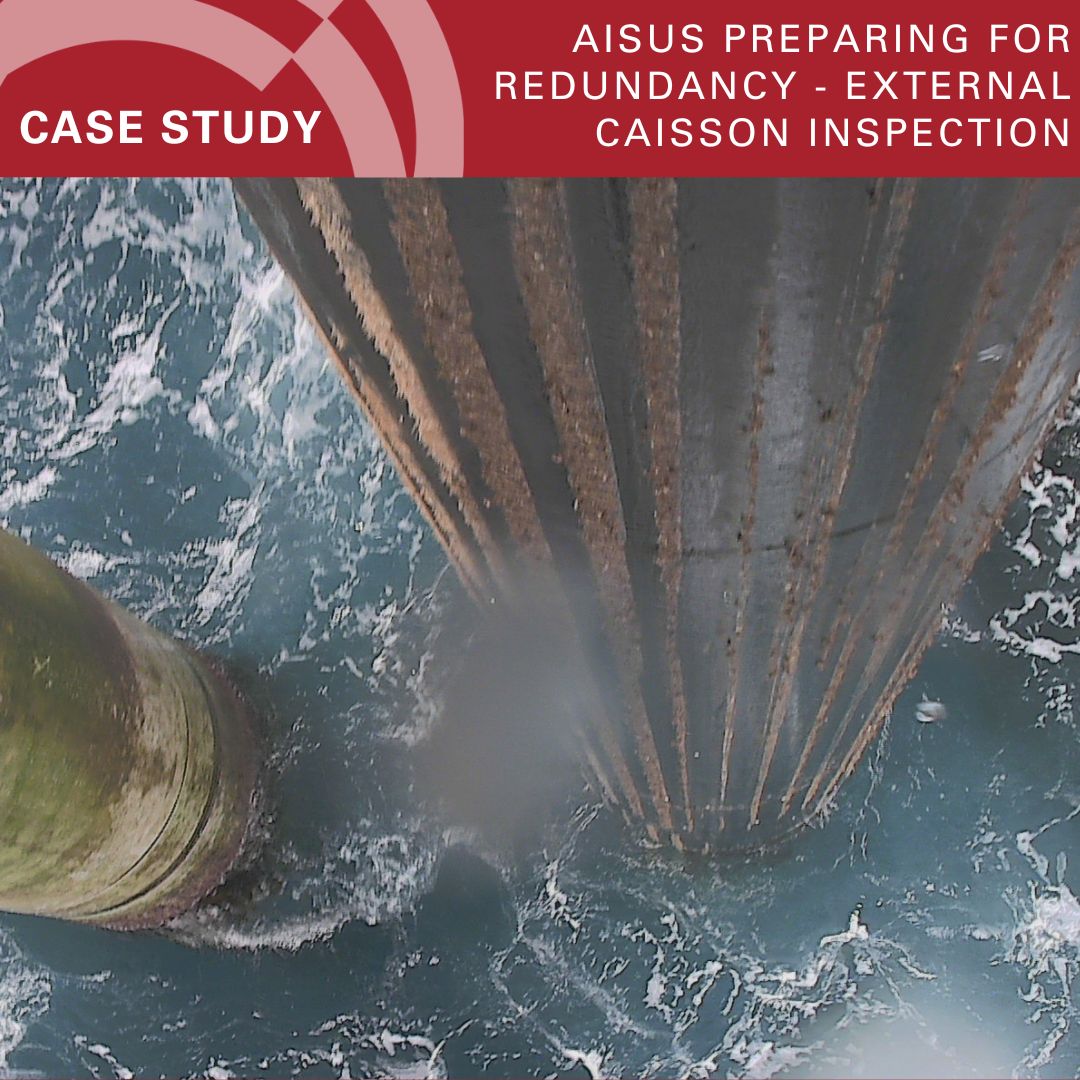

Preparing for Redundancy: External Caisson Cleaning and RVI

Overview AISUS was contracted by a North Sea operator to carry out external high-pressure jetting and remote visual inspection on two sea water lift caissons. The work formed part of the preparation for making the caissons redundant, with the key objective being the removal of marine growth, scale, and corrosion products, followed by a detailed […]

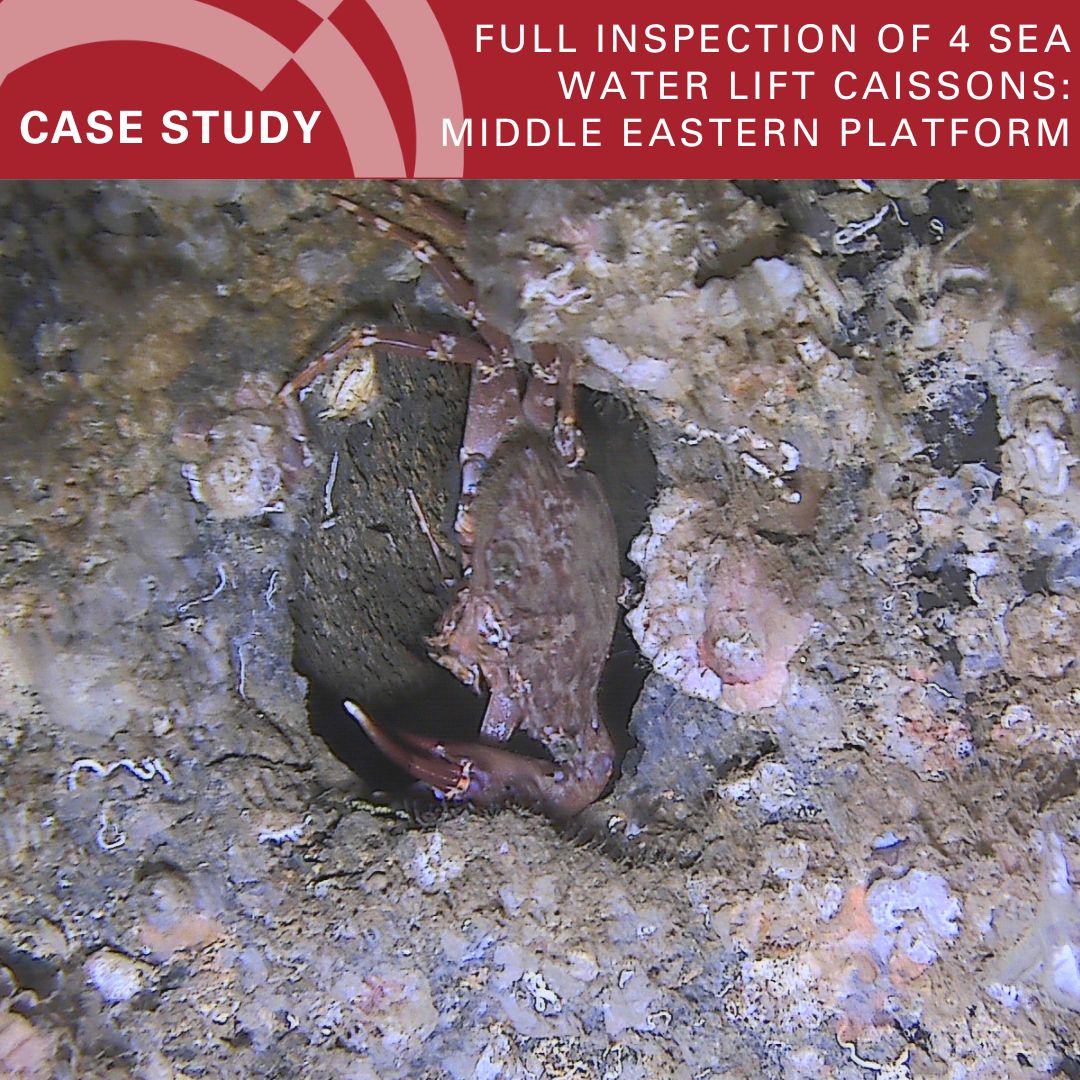

Full Inspection of 4 Sea Water Lift Caissons: Middle Eastern Platform

Overview AISUS were contracted to perform a full inspection of four sea water lift caissons on an offshore platform. Collecting UT data from topside to the termination grille and through the splashzone, to ensure structural integrity. The use of advanced remote inspection technologies, including the AISUS ‘SIRIUS’ ultrasonic scanner, enabled a detailed evaluation of the […]